NDSU Safety Office manages move of chemicals and research specimens to Sugihara Hall

While the distance involved wasn’t much more than a city block, the move of items from the labs in Ladd and Dunbar Halls to the new spaces in Sugihara Hall did involve its fair share of danger, risk, and surprises.

An important step in preparing the new Sugihara Hall laboratory spaces for students and faculty at the beginning of 2022 was to rehouse the chemicals and specimens located in the old spaces to the new facility. But it was a big step given that some of the items were caustic, flammable, or toxic and the specimens represented both historical and current research occurring in the NDSU departments of chemistry and biochemistry and geosciences.

NDSU safety office associate director of environmental health and safety Bret Mayo led the team charged with the move. The team packed and moved more than 16,000 containers in more than 1,000 boxes during the timeframe of November 29, 2021 to January 7, 2022, which Mayo said that was about the same amount of chemicals that he and the safety office would handle in a typical four-month period. Chemistry stockroom manager Brandon Gustafson was Mayo’s partner in the task. He noted that adding to the difficulty was the timing—three holidays, NDSU semester end and numerous weather events occurred during the time of the move.

In addition to Mayo and Gustafson, NDSU hazardous materials technician Aaron Ostlund and NDSU hazardous materials inspector Zach Smith made up the core team. Ted Jirik and Monty Botschner from the safety office were on standby to handle any accidents and members of facilities management built special ramps that were smooth and slip-resistant to minimize the amount of movement of chemicals loaded on carts.

Years of research

Dunbar Hall was put into service in 1964 and Ladd Hall was dedicated 53 years earlier in 1911. Both buildings served as home to the chemistry and biochemistry department labs and while the majority of items came out of Dunbar, content from some labs in Ladd were also part of the move. Dunbar Hall was demolished on March 3, 2022.

Given the buildings’ long history of service to chemistry and biochemistry research and education, both contained large amounts of substances used throughout the years. The group identified chemicals from almost every hazard class: carcinogens; highly corrosive acids and caustic materials; highly toxic solids, liquids and gases; highly flammable liquids and solids, unstable reactive materials, powerful oxidizers, and moisture reactive materials.

Maximizing safety

The process was complicated further given that certain hazard classes must be kept separate from others. Mayo explained a potential scenario that could occur if flammable materials came contact with oxidizers. “The resulting fire would be much hotter than a normal fire and would be very difficult to put out. In addition, fumes may be released when highly toxic materials get too hot that are lethal by inhalation.” The team was careful to never move toxic and flammable materials at the same time.

Mayo recalled a few discoveries of unanticipated chemicals the team made that provoked some surprise and anxiety. One nonlabelled item turned out to be water-reactive and created a vigorous fire when it was placed into a hazardous waste container that contained some wet paper towels. “Fortunately, we confined it in a fume hood and quickly snuffed out the fire. The remainder of the material was carefully neutralized and removed.”

Gustafson was similarly surprised when he was processing outdated chemicals before the move. He found a container of 1,3,6,8-tetranitrocarbazole that had been manufactured in 1965. Given its age, there wasn't a data sheet for it, but Mayo discovered that shipping the item had been discontinued in 1968 because of the danger associated with motion or friction when moving it. After further investigation of its properties, (revealed via a translation of an old Soviet Union military explosives manual and the 1962 Encyclopedia of Explosives and Related Items), both decided the best course of action was to have the chemical removed by the Red River Regional Bomb Squad for offsite disposal.

The Sugihara move gave the team an opportunity to implement a new electronic inventory system that promises quick and accurate sorting of the chemicals in the building. Its first use was in creating manifests that were attached to the outside of each box stated its contents, origin, and destination lab in Sugihara. While the team is still working on implementing the new system, they hope it will provide clear oversight into all substances found in the labs.

Historical specimens

Besides the chemicals, other special items needed to be moved including the current and historical chemistry and biochemistry and geosciences research specimens.

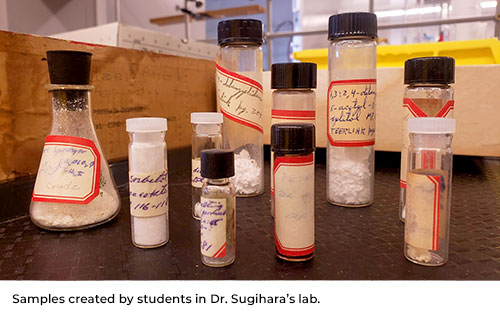

Mayo noted the intricacies of moving such specimens. “Some samples are in very fragile containers and as some can’t be purchased, they must be made, and these those took countless hours to create. Some are easily contaminated and mishandling them could result in the loss of thousands of dollars and hundreds of hours of preparation. Some of the biological samples would be very expensive to recreate if not irreplaceable.”

An additional complication was moving specimens stored at temperatures as low as -80C / -112F. To manage the special conditions required for moving these, Gustafson secured special heavily insulated rolling coolers and covered the specimens with dry ice to keep them cool during transport.

Mayo also recalled finding some very special items. “One pleasant discovery that we made were specimens that had been created and labeled in Dr. Sugihara’s lab.” These items will be preserved and displayed as part of the history of Sugihara Hall.

The Kanban Board

Once the items were packed, Mayo knew that they needed some sort of system to keep the move organized. His brother Joe Mayo provided him the answer. “Joe is well-known as a risk management consultant who manages large and very complex projects for government and industry so I asked his advice given the hazardous materials, the tight schedule, the number of people involved, and the constraints. He suggested using a Kanban Board. I presented the idea to Brandon and the team and we decided to go with it.”

A Kanban Board is a workflow management system that defines, manages, and improves services that deliver knowledge. Mayo said he valued how it visually represented a project. “You can look at the board and get an immediate overall view of the whole project as well as what you’re doing today. If you see a lot of clutter in one area, you are naturally drawn to that area and that is where you will usually find a bottleneck.”

The Kanban was an immediate value to the team. Mayo said that the daily meetings at the board were brief and on-point. Updated each day, the board also was an easy way to keep everyone in sync at any time.

Once the items were identified, packed, and inventoried and the move was planned out on the Kanban Board, the team still had one major issue to overcome.

“There was only one old and very slow elevator in Dunbar and it’s shared by all occupants, including another team that was handling the equipment and furniture move,” recalled Mayo. To minimize the downtime of waiting on the elevator, the safety office assigned themselves priority access to the elevator from 5:00am through 10:00am each day. After that, the other move team had access and the safety office could handle serving the needs of the rest of campus. “We provided very nearly the same level of service during the move as we had before,” he added.

All chemicals and specimens were successfully cataloged, moved without loss, and were in their new places when spring semester began in early January.

College of Science and Mathematics Dean Kimberly Wallin pointed out how this project stresses the importance of a safety culture and working together as a team. “The recent move from Dunbar to Sugihara clearly demonstrates the priority of safety. Bret and Brandon and everyone involved accomplished so much by trusting and respecting each other and by working together. Congratulations to the team for establishing a strong foundation of safety that extends to our research, teaching, and learning environments.”

Gustafson echoes Wallin’s sentiments about the importance of a safety culture. “I hope to use what we learned during the move and the processes involved as discussion points in our new Lab Safety Culture Task Force and the Lab and Chemical Safety Committee.”

Chemistry department chair and professor Greg Cook said he’d been eagerly anticipating the move to Sugihara after watching the construction from his Dunbar office. But he knew that having it ready for students was going to require that the chemicals and tools be in the labs on the first day of the semester. “Bret and Brandon’s strong partnership and the Herculean work of the entire group resulted in unprecedented results. Not only did they move an incredible amount of items in a short amount of time, but they did it safely and without mishaps. Thank you all for ensuring Sugihara Hall was ready to be the world class learning environment it is now.”